ADONY® Metering Pump

The ADONY® Diaphragm metering pump AH series is a cost-effective, direct-acting metering pump series.

By utilizing a vertical form flange motor and a variable pump structure, this model saves space, and its design and production makes it durable enough for use in any environment, including chemical factories, water and sewer systems, sewage treatment plants, industrial wastewater treatment plants.

With their many years of experience, the pump experts at Nikkiso Eiko have cultivated technology and quality materials to meet the various needs of the customers.

Features

Vertical mounted motor enables space-saving

PVC, SUS304, SUS316 diaphragm heads available

Various connection types available: Flange, Union or Hose (AHA01-32:PVC only)

Durable and simple oil-bath drive unit

Application

Chemical Metering and Dosing (pH control), sampling

Waste water treatment plants

Water processing plants

Chemical plants

Paper manufacturing plants

Food processing plants

Mining/Iron plants

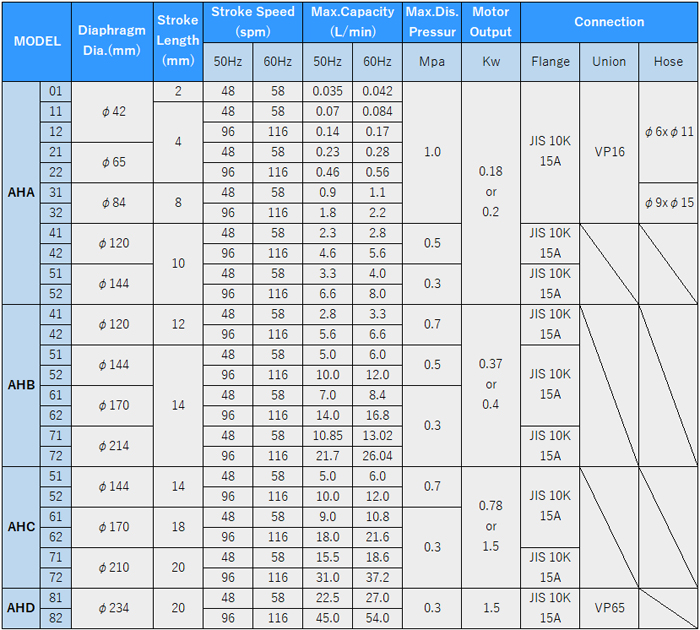

Specifications

| Flow rate (L/min) | Minimum: 0.035 (50Hz), 0.042 (60Hz) Maximum: 45.0 (50Hz), 54.0 (60Hz) (Option:dual heads is possible) |

| Maximum discharge pressure (MPa) |

1.0 MPa (AHA01 to 32) ,see catalog for other models Repeatabillity of preciese pumping ±2% |

| Stroke length control | 1:4 |

| Rotation control | 1:10 |

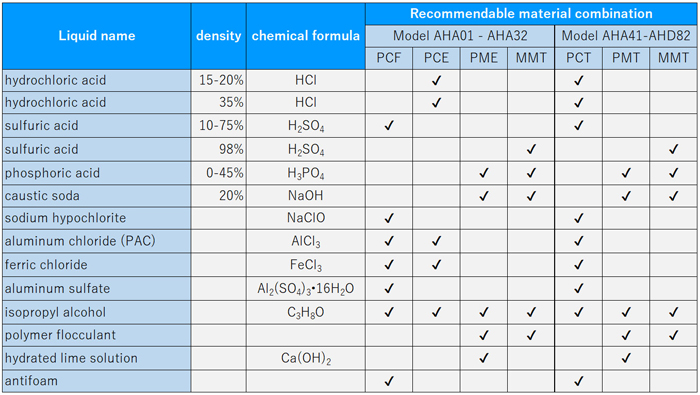

Recommendable material combination

Note: This table is used as a reference for model selection, and is not a guarantee of the material.

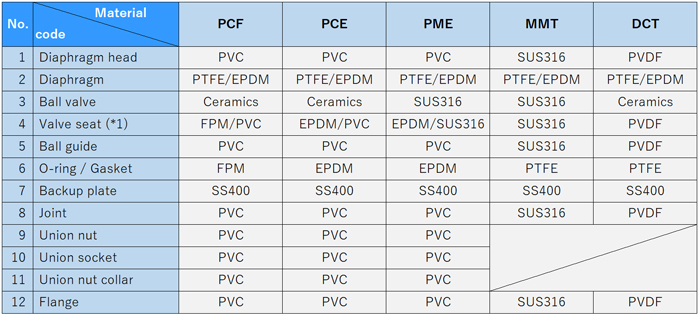

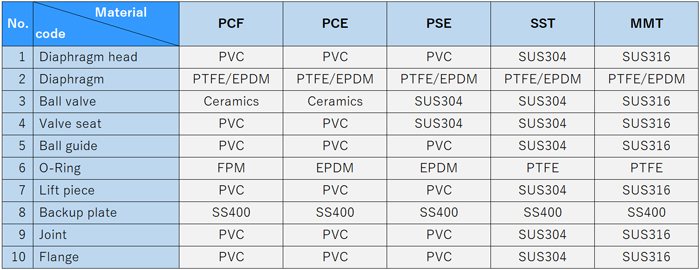

Liquid end material composition for each model

Model No. AHA01~32 (Diaphragm head : SUS & PVDF; Flange type only)

(*1) Valve seat material : AHA01~22 / AHA31~32

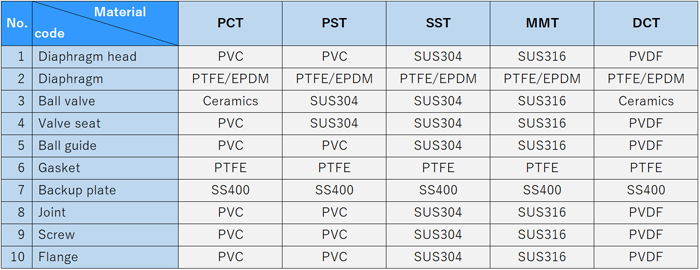

Model No. AHA41~52, AHB and AHC

Model No. AHD81~82

Series

Electro servo unit (For AH) series

|

|

Plunger type metering pump SK series

| This pump has a wide range of applications such as high pressure line metering in chemical factories, boiler drug infusion,built-in equipment metering, etc. It succeeds in being able to withstand long-time usage due to its solid construction. By regulating the crank portion’s stroke length, the plunger pump has a linear variation between 0 and 100%. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SKA Plunger type metering pump | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Material composition

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SKC Plunger type metering pump | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Material composition

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||